chemical & physical process

What is generally referred to as the ‘lime production process‘ actually involves the burning and processing of by-products obtained from different types of minerals available in nature.

For the sake of explanatory clarity, the chemical diagram below is not so distinctly divided into the minerals that are used industrially, which represent a more or less complex mixture of the types mentioned.

Calcium Carbonate | CaCO3 |

Magnesium carbonate | MgCO3 |

Dolomite | CaCO3 MgCO3 |

Hydraulic Limestone | CaCO3 MgCO3SiO2 Fe2O3 Al2O3 |

This mix of possible chemical compositions of the starting mineral obviously leads to a greater complexity of the “real” material behaviour both during its work and in terms of chemical and physical characteristics of the finished products of the productive process.

BASIC CHEMISTRY OF THE LIME PRODUCTION PROCESS

Decarbonation of limestone and dolomite

| CaCO3 | + | Kcal | ↔ | CaO | + | CO2 | (+ 760 kcal/kg) |

| 100 | 56 | 44 | |||||

| MgCO3 | + | Kcal | ↔ | MgO | + | CO2 ↑ | (+ 723 kcal/kg) |

| 84 | 40 | 44 | |||||

| CaCO3 MgCO3 | + | Kcal | ↔ | CaO MgO | + | 2CO2 ↑ | (+ 723 kcal/kg) |

| 184 | 96 | 88 |

Hydration of calcium and magnesium oxides

| CaO | + | H2O | ↔ | Ca(OH)2 | + | Kcal | (- 273 kcal/kg) |

| 56.1 | 18 | 74.1 | |||||

| CaO MgO | + | H2O | ↔ | Ca(OH)2 MgO | + | Kcal | |

| 96.4 | 18 | 114.4 | |||||

| CaO MgO | + | 2H2O | ↔ | Ca(OH)2 Mg(OH)2 | + | Kcal | (- 211 kcal/kg) |

| 96.4 | 36 | 132.4 |

Recarbonation of calcium and magnesium oxides

| CaO | + | H2O | ↔ | Ca(OH)2 | ||

| 56.1 | 18 | 74.1 | ||||

| Ca(OH)2 | + | CO2 | ↔ | CaCO3 | + | H2O |

| 74 | 44 | 100 | 18 |

DECARBONATION

The first group of reactions summarises the decarbonation process of the three main types of carbonates existing in nature.

They represent the reaction that, industrially, takes place in the limestone kiln when, starting from the mineral coming from the quarry and providing a prefixed quantity of heat, the dissociation of the carbonate (CaCO3) in an oxide (CaO) and in carbon dioxide (CO2) is obtained.

The reaction is endothermic and therefore requires a caloric input obtained by using a fuel.

It takes 760 kcal/kg to decarbonate CaCO3 and 723 kcal/kg for MgCO3.

Note: In the following, unless otherwise noted, we will refer to the case of calcium carbonate and/or lime oxide for simplicity of exposition, but in the case of the other types of components mentioned, the mechanisms by which the reactions take place are quite similar.

The dissociation of limestone takes place in five consecutive steps:

- In the preheating zone of the kiln, the heat generated by the fuel is transferred from the combustion gases to the ore to be decarbonated, which passes from ambient temperature up to 800° C.

- At a temperature of 800° C, the pressure of the carbon dioxide produced by dissociation is equal to the partial pressure of the CO2 in the gases passing through the kiln. As soon as the temperature begins to rise above the decarbonation value, the surface layer of the limestone begins its decarbonation. When the surface temperature has reached about 900° C, a 0.5 mm layer has decarbonated (5% of the total mass).

- At a temperature of 900° C, the partial pressure of CO2 is greater than 1 atmosphere and the decarbonation process can proceed from the surface towards the centre of the limestone chunk.

- Throughout the decarbonation process the temperature of the mineral remains almost constant and if for reasons related to the industrial process the temperature rises above the decarbonation point or the chemical composition of the limestone used reduces the decarbonation temperature, the crystalline structure of the lime produced starts to collapse (sintering).

- Once decarbonation is complete, the lime is cooled with the air entering the kiln, which rises inside the preheated shaft to become combustion air.

The main factors affecting the speed of decarbonation are:

- size of the limestone and its shape (minimum size): this factor affects the migration time of CO2 from the centre of the decarbonating mass to the surface.

- particle size distribution of the limestone used: a different particle size distribution of the limestone imply a different exchange surface between limestone and hot gases and therefore a different heat transfer rate.

- chemical composition of the limestone: the presence of impurities or magnesium carbonate imply a variation in the theoretical temperature at which decarbonation starts.

- speed of the gases inside the kiln and their temperature: the speed of the heating fluid and the temperature gradient are factors which affect the rate of energy transfer from the gases to the mineral.

- pressure of the gases inside the kiln: Higher pressures require more pressure from the CO2 to migrate into the limestone.

HYDRATION

The term hydration or slaking of lime refers to the process by which lime oxide (CaO) is transformed into lime hydroxide (Ca(OH)2).

From a chemical point of view, there is only one type of reaction, but from an industrial point of view, there are two different types of process.

One is the hydration process itself, in which the oxide is reacted with the stoichiometric amount of water (32% H2O) to obtain a hydroxide in the form of a powder containing a maximum of 1.5% free water.

The other is the slaking process where the lime oxide is made to react with a quantity of water much greater than the stoichiometric content, obtaining a lime hydroxide in suspension with very variable concentration values depending on the use required.

The chemical nature of the hydration reaction is very elementary, but the kinetics of the reaction, linked to crystallisation and agglomeration, is much more complex and depends not only on the physical and chemical characteristics of the oxide to be extinguished, but also on the way in which this simple reaction is carried out.

At temperatures below 350 °C, the oxide reacts completely with water, giving rise to an exothermic reaction with the development of 276 kcal/kg. CaO, at higher temperatures the reaction occurs in the opposite direction resulting in the separation of the reaction water.

Magnesium oxide is not very reactive with water and under normal conditions only 25% of it reacts.

In order to achieve complete hydration of MgO, it is necessary for the reaction to take place at a temperature above 100° C using pressurised equipment.

The main factors affecting hydration are:

- lime reactivity of the oxide used (T60)

- apparent density of the lime oxide

- particle size distribution and top cut of the oxide

- percentage of carbonate (L.O.I.)

- percentage of sulphur

- percentage of magnesium oxide

- temperature at which the hydration process takes place

- efficiency of the oxide-water mixing system

- additives used in the drafting water

In the industrial context, the hydration reaction is carried out using hydrators, in the case of the production of powdery hydroxide on a dry basis (stoichiometric water) and rotating drum slackers if the production of lime hydroxide in slurry form (excess water) is desired.

Both systems are schematically speaking mixers in which mechanical agitation produces very close contact between the lime oxide and the reaction water.

RECARBONATION

The recarbonation reaction is the last reaction in the life cycle of lime, it controls the process that transforms lime back into carbonate by reabsorbing CO2 from the environment and giving back to lime the chemical and physical characteristics that the original limestone had.

This is the fundamental reaction that allows lime, once applied to a wall, to set and harden.

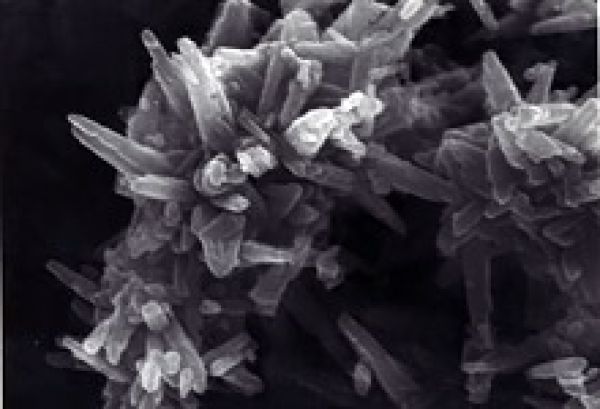

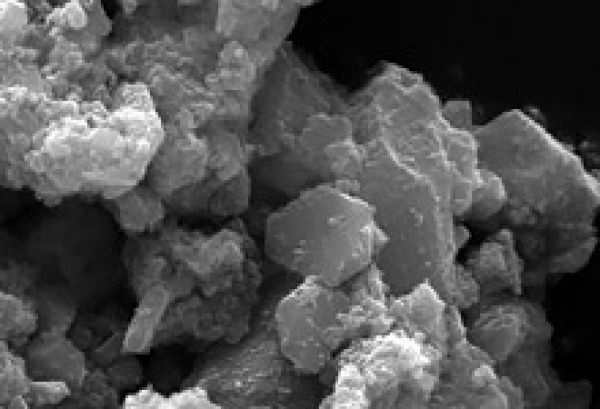

Man has learnt to control this reaction for his use in the production of PCC (Precipitated Calcium Carbonate), a process in which by controlling the parameters influencing recarbonation it is possible to modify the grain size and morphology of the calcium carbonate produced.

At ambient conditions the recarbonation of lime is very modest, but from 290 °C up to 600 °C the speed of recarbonation increases rapidly, exponentially increasing the affinity of CaO with CO2.

The speed of this reaction is also significantly increased by both the specific surface area of the oxide and the speed with which the oxide is mixed with carbon dioxide. It can be seen that magnesium oxide has significantly longer recarbonation times than calcium oxide.

The presence of water, both in the form of moisture and steam, enables rapid recarbonation to take place even at ambient temperature and pressure, since water acts as a catalyst in the reaction.