Machines and equipment

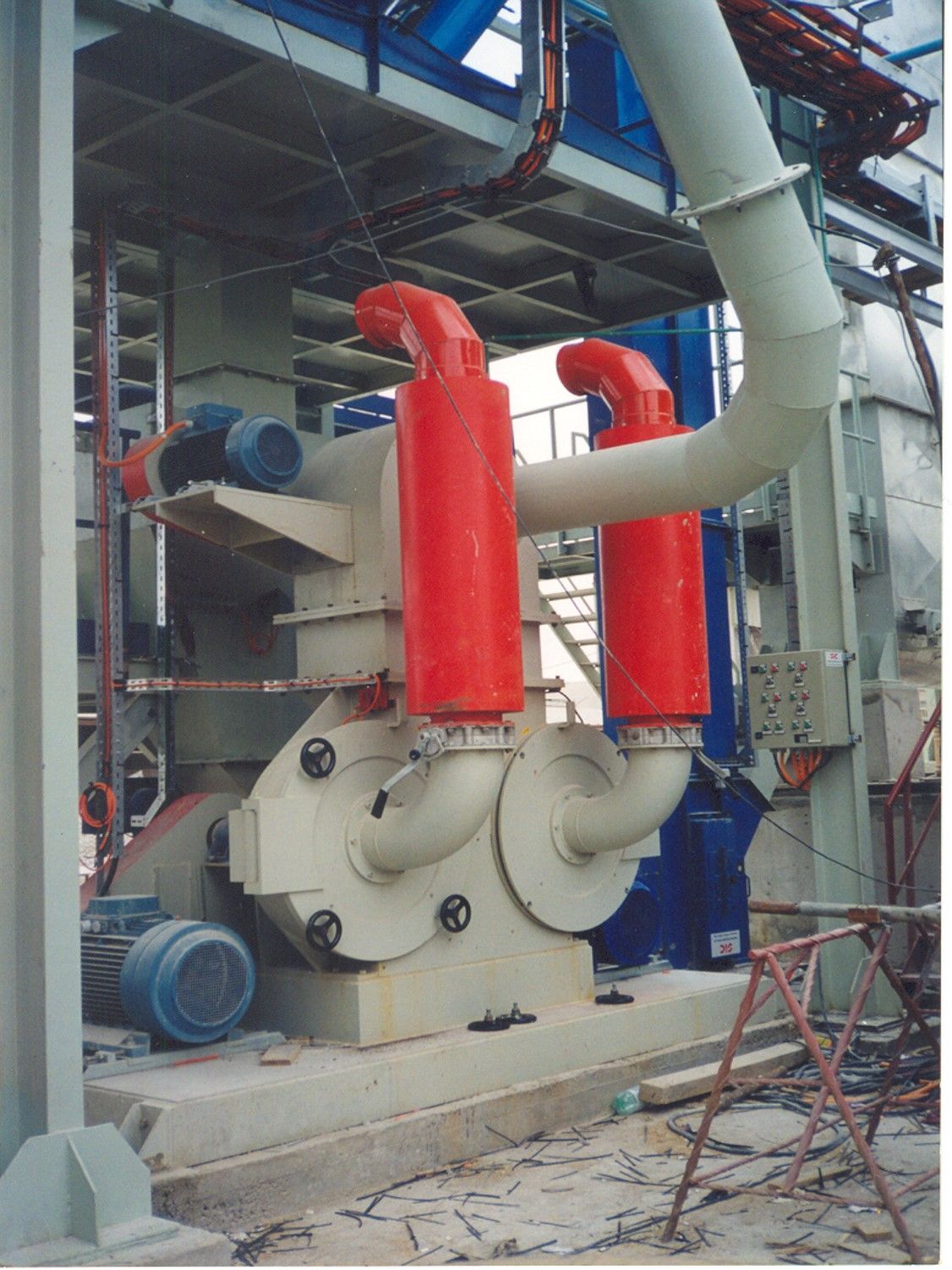

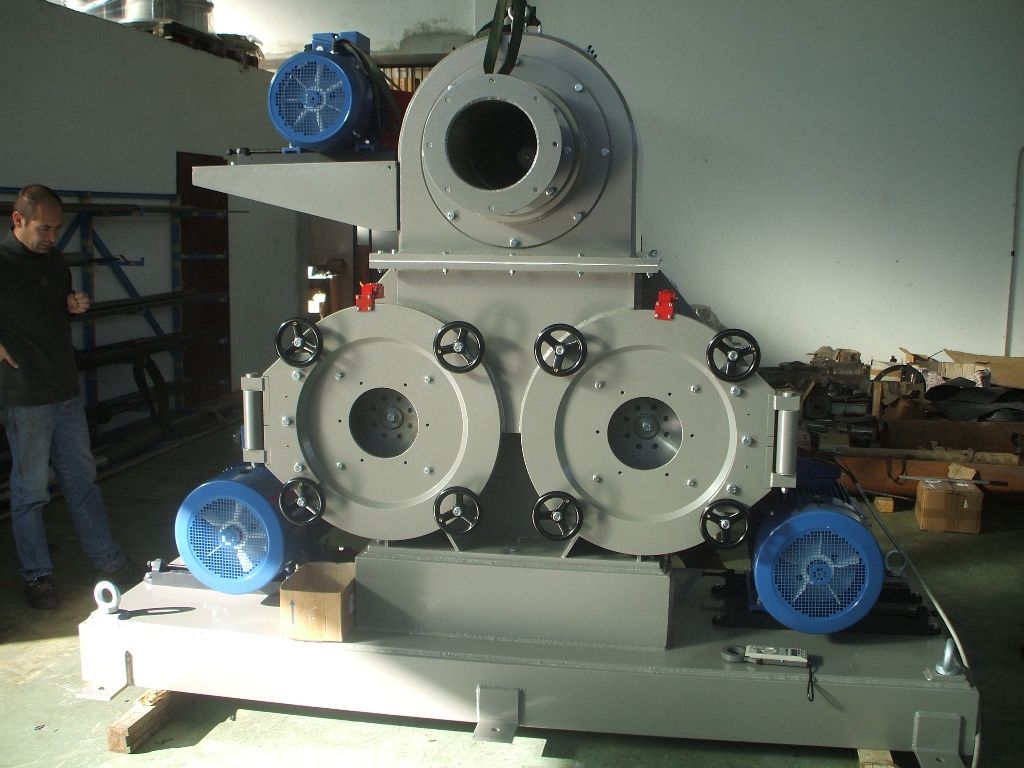

“S” Micronising Mills

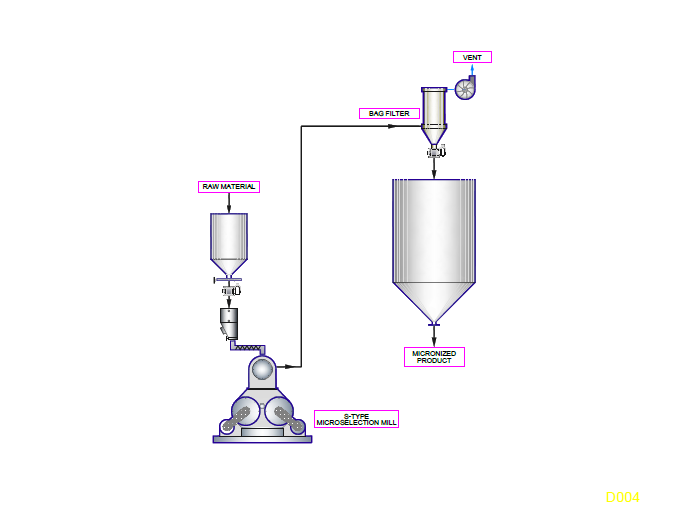

The SIC “S” type Selector Mill represents one of the most modern solutions to the problem of fine grinding and selection of minerals.

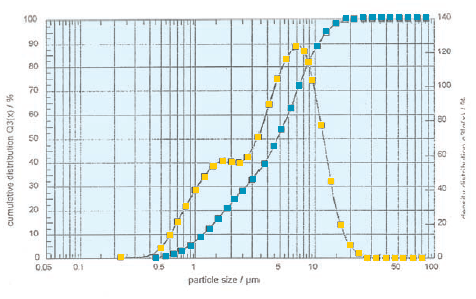

Our selector mill combines the efficiency of a double rotor grinding system, where the product to be ground is forced into intersecting trajectories, with a new generation air separation system.

The combination of the selection unit directly with the grinding unit enables the finished product to be extracted continuously without over grinding the product, thus significantly reducing energy consumption.

By acting solely on the inverter to adjust the speed of rotation of the selector unit, it is possible to continuously vary the top-cut of the material produced without the need for mechanical operations.

The compact dimensions, the absence of vibrations, the low noise level and the pneumatic extraction and transport system of the finished product from the machine, make the installation of the SIC “S” type selector mill extremely easy and cost-effective, even within existing plants.