HISTORY

1840 – 1880

1880 – 1900

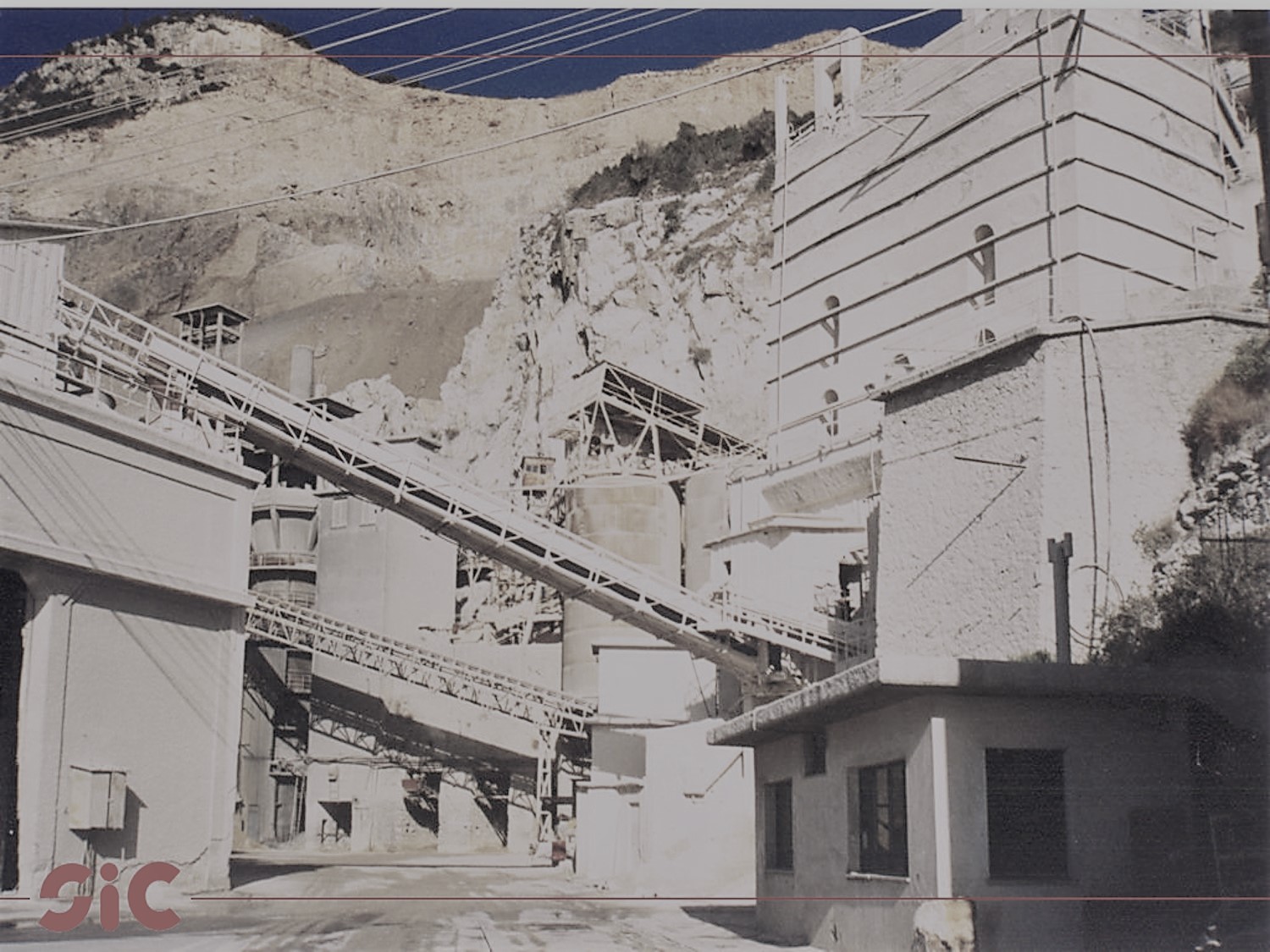

The quarry was to become the main production centre for the company for over a century and a half.

1900 – 1920

Giacomo and Angelo’s sons built the first and second continuous kilns with coal combustion, based on their first experiences in neighbouring France. The kilns are made of concrete, have a round cross-section and an output of 20 T/D.

1920 – 1930

Arturo Ghigliazza set up and directed the first research and development team for new technologies to be applied to lime production and quarrying.

1933

The success of the innovations is such that other lime manufacturers ask to apply these technologies in their factories.

1935

Arturo Ghigliazza moved to Milan, a large industrial centre in northern Italy, to better follow the development of new technologies. In parallel with his work as a technical assistant for the family company, he started to design and build lime plants for other manufacturers.

1936

The first two Italian kilns abroad are built in Ethiopia.

1945

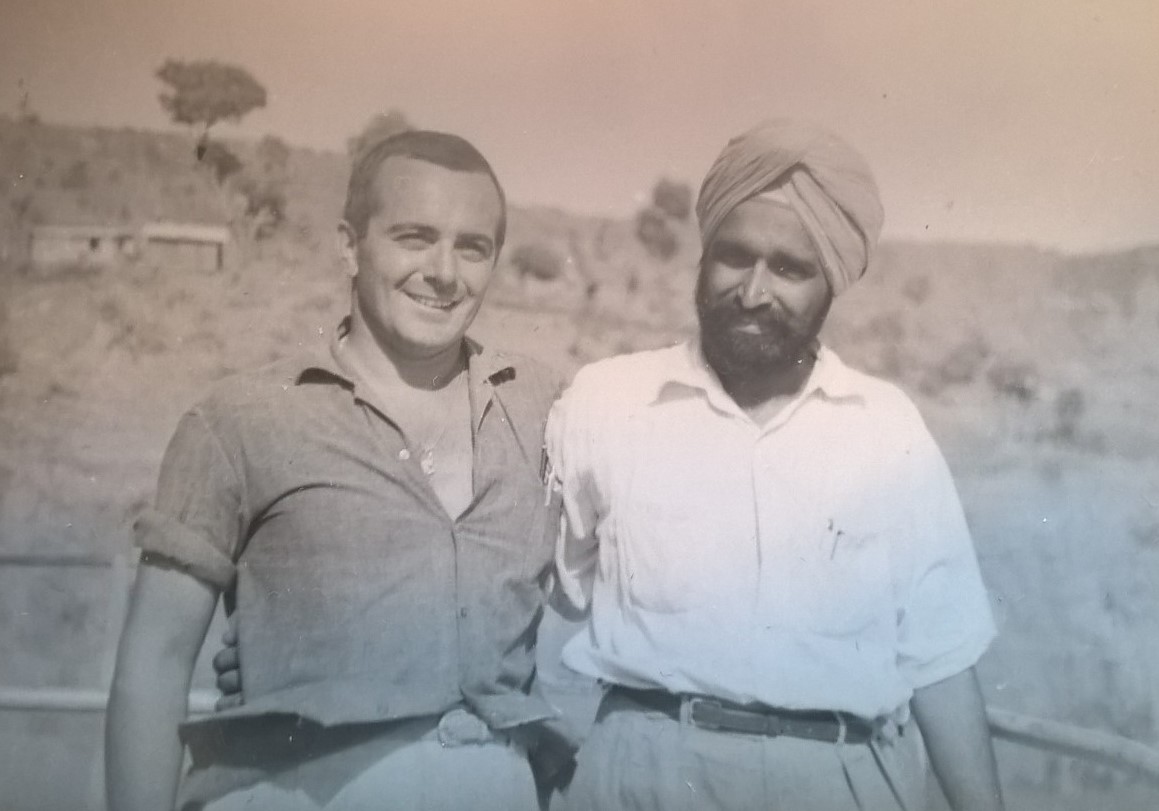

At the end of the Second World War, Arturo Ghigliazza was joined by his nephew, Franco Accinelli, in designing and building plants for the lime industry. The family business was transformed into an industrial enterprise.

1945

The family company is transformed into a public limited company: Fratelli Ghigliazza S.p.A. is born, with three production units (Finale Ligure, Genoa, Lucca).

1948

Italy’s first kiln with fuel oil combustion was built in Merano.

1954 – 1955

Natural gas arrived in Italy and the first conversions of coal-fired furnaces began. These were the first steps in an evolution that would lead to the birth of CBK kilns.

1958

1964

1980

1981

1982

1984

1990

SIC builds first PCC plant in Mexico.

1991

Once the study and testing phase has been completed, SIC begins industrial production of the “S” series micronising mills.

1995

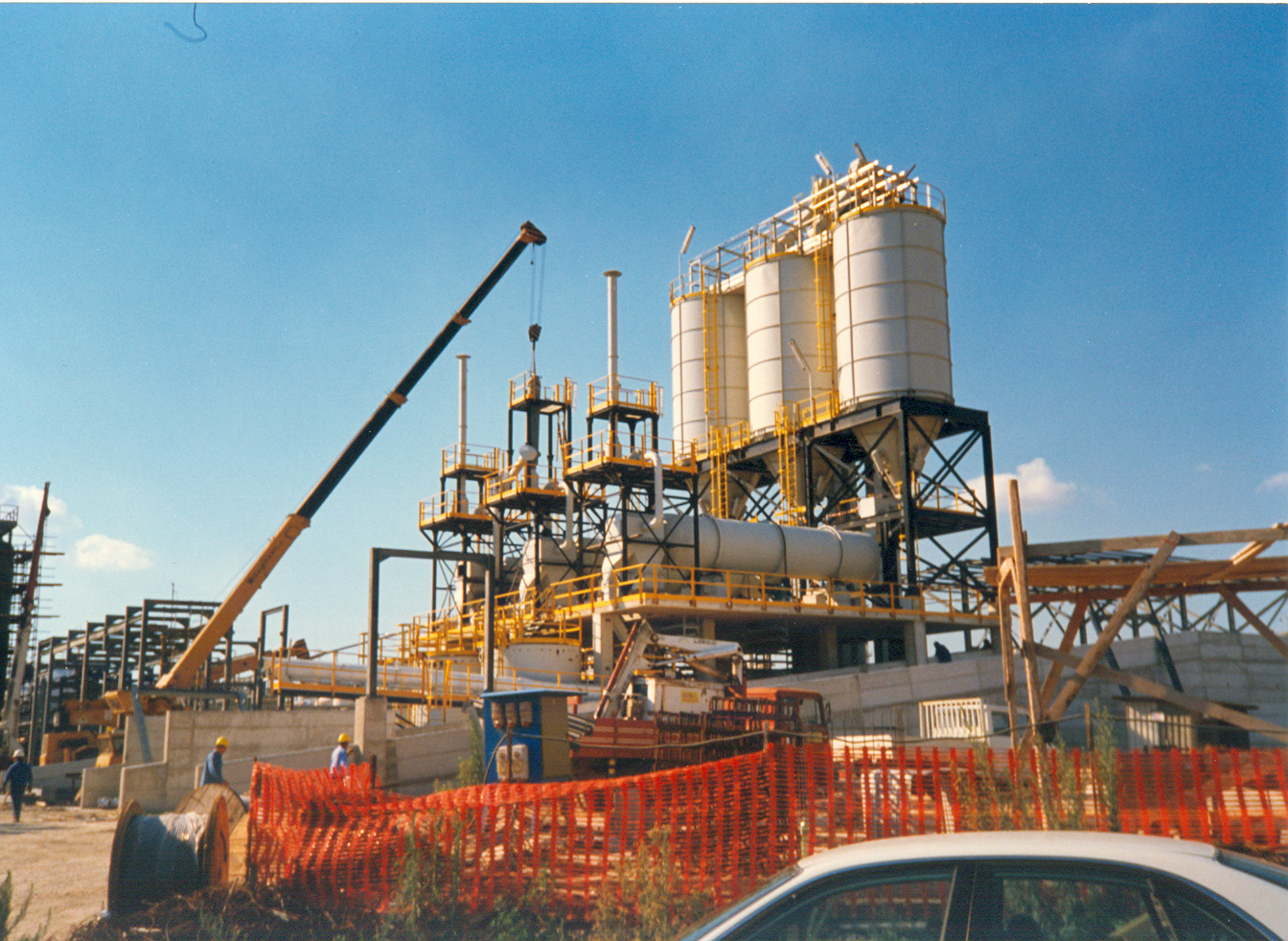

On behalf of the national petrochemical company ENI, one of the largest plants for the production of lime milk for chemical use is built with a slaking capacity of 30 Tonn CaO/H.

1997

1998

The development of the “S” series mill technology leads to the birth of the “HPS” air separators. This completes a revolution that leads to a new way of designing hydration systems.

2002

For the first time in Europe, on behalf of Ciment France / Italcementi, a complete line is created for the production of hydraulic lime for green/bio-building using modern equipment.

2007