History of lime

Today, lime is one of the most widely used chemical/industrial products in the world, with a total annual world production of over 300 million tons.

But its history dates back to the earliest days of human history on Earth.

The discovery of lime by prehistoric man is thought to have taken place at the same time as the discovery of other natural binders, such as clay and gypsum, and before the discovery of metals because of the lower temperatures at which it is burned.

It is reasonable to assume that the discovery came about by chance, noting that in some geographical areas, when stones were placed around fire, they changed their structure when in contact with the fire, turning to dust and then, when combined with water, became a plastic mixture, which, when dried, lost its plasticity and returned to the rigidity of the original stone.

The discovery of binders is to be regarded as a very important step in human evolution, as it was one of the first opportunities for man to modify nature to his advantage.

The first historical evidence of the systematic use of lime or lime and gypsum compounds by humans has been found by archaeologists:

- in Cajenu (Turkey) where lime was used in the form of a mixture with sand to cover terraces as early as 8000 BC.

- in Yiftah (Israel) floors made of lime and stones were found on a clay base (7000 BC).

- in Lepenski Vir (Serbia) have been found floors of houses made with mortars based on lime, sand and clay (6000 B.C.)

- in Shersi (Tibet) lime was used for the construction of pyramids (3000 B.C.)

- in Kafaje (Mesopotamia) a lime kiln dating back to 2450 B.C. was found.

In Cairo (Egypt) lime was used for the structural construction of the pyramid of Cheops, lime mixed with gypsum was used to make the plaster on which the hieroglyphics were painted, and even the closing of the door of the tomb chamber was made with stones and lime mortar (2500 BC).

The walls of Jericho (23 km from Jerusalem) were built in 1000 BC to protect the city from enemies, and the Bible tells us that they were destroyed by the Jews when they settled in the Promised Land.

In the period in which the use of lime was spreading in Italy thanks to the Romans and in numerous other parts of the world, even very far away from each other, contemporary human artefacts made with the use of lime have been found, we remember in this regard in Central America the pyramids and the Maya and Incas palaces, in China the great wall of the Chin dynasty in 228 B.C., in India and Mongolia numerous temples and private houses.

Although the use of lime by the Romans was at a later stage, the first known uses being the aqueduct and the Appian Way dating back to 300 B.C., we actually owe the codification of lime, how it was used and how it was produced to Roman civilisation.

Empedocles, a poet and scientist from Magna Graecia, who lived between 482 and 426 BC in the Sicilian city of Agrigento, describes numerous natural phenomena in his book ‘Of Nature’ and was the first to describe the ‘lime cycle’. Empedocles writes: ‘there is magic in taking a stone from the earth, demolishing it with fire, shaping it with water and, thanks to man’s genius, regaining with the help of air a solid material as hard as the initial stone‘.

Due to the prevailing geology of their territory, the Romans, in the initial phase of using lime, were only familiar with the properties of aerated limes (limes capable of setting using air) mixed with sand.

Soon, however, the Romans imported the technology of preparing hydraulic binders (lime-based binders that set with water) from the Greeks and Phoenicians. Hydraulic binders were obtained by the Greeks and Phoenicians by mixing aerial lime with volcanic sands from the islands of Santos and Thera (now Santorini).

These types of materials mixed with aerial lime allowed for greater performance, in terms of resistance, than those obtained with aerial lime mixed with “clean” sand and also allowed the mortar to set even underwater, thus allowing the construction of ports and bridges with parts immersed in water.

For the production of their hydraulic mortars, the Romans mainly used deposits of pozzolana, [volcanic earth near the city of Pozzuoli (Naples)]: it is from the name of this city that the name, still used today, of ‘pozzolanic cement‘ is derived.

The Romans probably imported the technique of producing mortars with hydraulic characteristics from the Minoan civilization of Crete by mixing lime with ground or crushed bricks, tiles and pots (crock crushed).

Legend has it that ancient Rome had settled on seven hills, but the Romans during their history artificially created the eighth hill, the Testaccio hill.

In the days of the Empire, all foodstuffs were transported using terracotta amphorae weighing about 30-40 kg each, which, once emptied of their contents, had to be sanitised and stored.

The Romans began to store the empty amphorae near the river port of the Tiber river, the amphorae were covered with lime to prevent fermentation and putrefaction of food residues which caused miasmas.

Over the centuries, this storage of amphorae reached a height of 80 metres, creating Rome’s eighth hill. Thanks to the reaction between lime and clay, this new hill became so stable that today it is completely covered by modern buildings.

As the empire expanded, the Romans exported the technology of lime production throughout Europe. It was customary for the Roman legions to build a lime kiln in the vicinity of the military camp when settling in new territories, in order to have lime available at all times for building aqueducts, roads, harbours, sanitation, agriculture, leather tanning and medical applications.

The lime technology of the Romans reached such a high level that in 27 B.C. they were able to build the dome of the Pantheon in Rome which, with its 43 m diameter, remained the largest dome ever made by man until the 20th century.

A great deal of work was done by some Roman authors to spread the good use of lime by creating a “regulation” for its production, ageing and use.

The earliest known text in this respect is ‘De Architectura‘, a ten-volume work written by Marcus Vitruvius Pollonius in 13 B.C. Vitruvius’ monumental work deals with many features of the production and use of lime: it is surprising how some of the notes in the text are still reflected in the daily lives of lime producers or users today.

We mention only one of these notes below, as it seems to us to be quite emblematic. With regard to the preparation of the lime, we quote Vitruvius: “When the maceration is done, and diligently prepared for the work, take an axe and as you chop wood, do the same to the macerated lime in the basin: If the axe comes across pebbles, it will not be well macerated; if the iron is extracted dry and clean, it will indicate that the lime is lean and dry; if it remains stuck to the iron like gluten, it will indicate that it is fat and well macerated, and this will be more than sufficient proof to believe it to be well macerated”.

Try asking a technician involved in lime putty production today how to recognise good lime putty without using laboratory tests and you will see that the answer is exactly the one given by Vitruvius 2000 years ago!

Pliny the Elder (23 – 79 A.D.) also took up the experiences of Vitruvius, of whom he was an admirer, and went into some specific engineering issues for the construction of lime kilns in his book “Naturalis Historiae“. Pliny takes up and mentions in his text the codification of lime kiln construction methods based on what had been established at the time by the guild of ‘calcis cocitores‘ (lime burners) in Rome.

In 75 A.D., the Greek physician Descor reported the benefits of using saturated lime water to treat stomach pains (acidity).

Saint Augustine Bishop (354 – 430 AD) born in Algiers, known to most as one of the leading theologians of the Christian church, was also an esteemed civil engineer and took up and improved the construction methods already reported by Vitruvius and Pliny.

The fall of the Roman Empire and the beginning of the Middle Ages led to a loss of the “lime knowledge” that the Romans had developed.

In this historical period, the quality of lime and artefacts became very poor, many of the artefacts from this period were lost, worn down by time and the weather as they were often ‘badly built’.

Lime kilns built in masonry and with some technological ‘cunning’ during the period of the Roman Empire, now give way to rudimentary temporary furnaces (field kilns) that were little more than holes in the ground surrounded by stone walls.

Historical records of the production and use of lime during this period suggest that we have regressed by 1,500 years.

In England and France too, the period of the Saxons and Normans (450 – 1,150 A.D.) corresponds to a period of great decline in building techniques and lime production.

It was in the Middle Ages, however, that alchemists discovered that by mixing lime with wood ash it was possible to make potassium carbonate caustic to produce a form of lye which was the basis for soap production.

Shakespeare mentions in his works how in 1217 lime was used by the English to throw at their French enemies, initiating the first form of chemical warfare in history.

Some authors tell us that during the 9th, 10th and 11th centuries, all knowledge of the correct use of lime and mortar was lost in England and France.

Today, the analysis of the mortars used for building in this historical period leads us to highlight how often the sands were used “dirty”, not selected, badly mixed and the use of hydraulic mortars or crock crushed had completely disappeared.

In Europe, the “lime” condition only began to improve in the 12th century and continued until the 14th century when the advent of the Enlightenment led to the translation from Latin of the classical texts of Vitruvius and Pliny, rediscovering the construction and production methods mentioned by these authors.

In the seventeenth century, during the great hydraulic engineering works carried out for the construction of the Palace of Versailles, French scholars such as De La Faye, Lariot and others resumed the study of Roman technologies that allowed the construction of steady, long-lasting buildings.

In 1805 Jean Rondelet published an authoritative book entitled “Treatise on the Art of Building” in which he analysed and attempted to explain the reasons for the performance obtained with mortars by the Romans, attributing this merit not so much to the lime itself as to the conditions under which it was used, the care taken in the composition of the aggregates, the mixture and the compression of the mass.

It was only in the following years, with the development of science, that Rondelet’s empirical insights were confirmed and scientifically validated.

In the middle of the 1700’s an important step for the world of lime took place, first Josef Blank from the University of Glasgow and then the physicist Lavoisier isolated and identified CO2, starting to give a scientific form to the processes of decarbonation of limestone and recarbonation of lime.

In these early years of modern chemistry, the simplicity of the decarbonation process attracted the interest of many scientists who tried to understand its secrets.

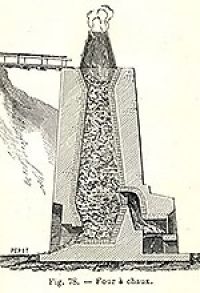

In 1766, De Romecourt published a detailed study entitled ‘The Art of Lime Burning‘, in which he was the first since the Roman Empire to attempt to describe the engineering and economic aspects of the industrial lime burning process.

In 1818, the Frenchman Vicat was the first to establish rational principles for the production of modern hydraulic lime.

In 1867 Debray measured the dissociation pressures of calcium carbonate, measurements which were later taken even more accurately by Le Chatelier in 1886.

In 1935 Searle described in a text the technology and main constructional aspects of 40 known kiln types.